- 11.1V

- 電流制御

XM540-W150

DYNAMIXEL is a robot exclusive smart actuator with fully integrated DC Motor + Controller + Driver + Sensor + Reduction Gear + Network in one DC servo module.

The DYNAMIXEL-XH / XM Series offers a variety of control techniques based on high-performance current sensing algorithms.

It adopts the aluminum case and adopts the new technology such as the hollow cable fastening structure for users’ convenience.

1. 6 Operating Modes

(Torque Control, Velocity Control, Position Control, Extended Position Control, Current based Position Control, PWM Control)

2. Profile Control for Smooth Motion Planning

3. Improved Heat Sink Featuring an Aluminum Case

4. Hollow Back Case Minimizes Cable Stress (3-way-routing)

5. Direct Screw Assembly to the Case (without Nut Insert)

6. Energy Saving (Reduced Current from 100mA to 40mA)

7. 28.4% reduced volume compared to the MX-106

8. Support synchronous control mode

9. Support external I / O port support

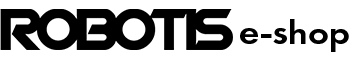

| XM540-W150 | 1 |

|---|---|

| HN13-N101 | 1 |

| Teflon Washer (for Horn Assembly) | 1 |

| Robot Cable-X4P 180mm | 1 |

| Robot Cable-X4P (Convertible) 180mm | 1 |

| 3P Sync Cable 160mm | 1 |

| Wrench Bolt WB M2.5x5 | 16 |

| Wrench Bolt WB M2.5x4 | 10 |

| Wrench Bolt WB M3x8 | 1 |

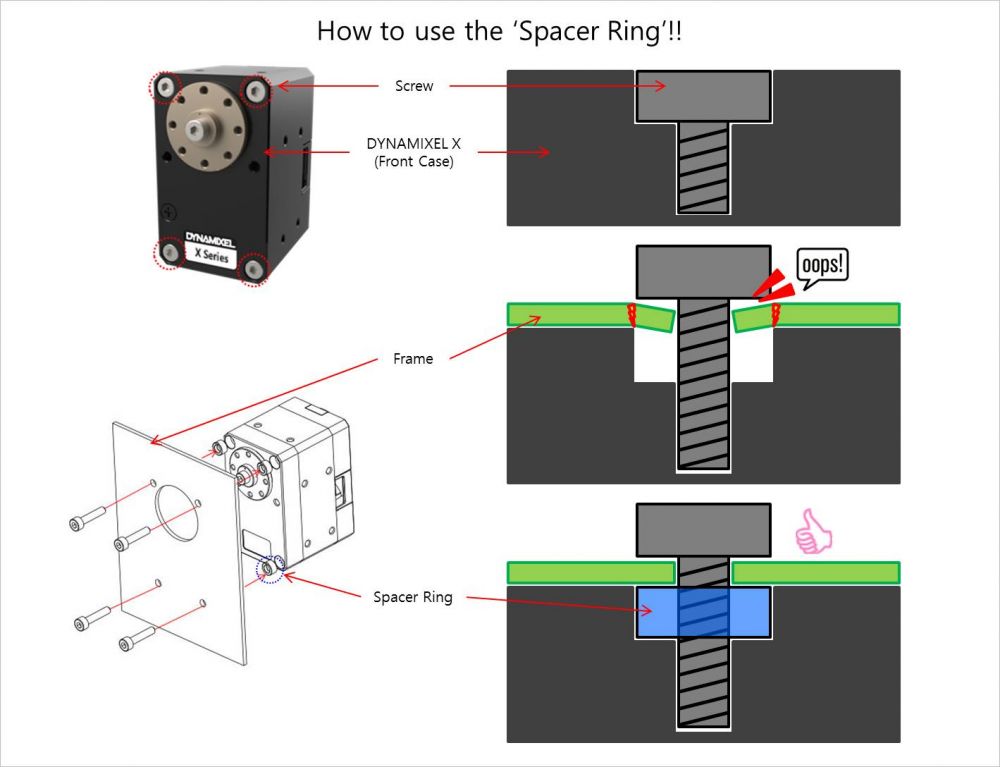

| Spacer Ring | 8 |

Controller : OpenCM9.04 485 Expansion Board, OpenCR1.0

Interface : USB2Dynamixel, U2D2

ID : 1

Baud Rate : 57600bps

(User can change various settings including ID and baud rate according to environment)

DYNAMIXEL-X Series cable assembly through hollow case

Organize the entangled cable before assembling the back case.

Do not assemble the back case with entangled cable. The entangled cable can be squashed by the case and cause communication error.

If you use two cables through the hollow case, the cables will be damaged.

Use only one cable through the hollow case.

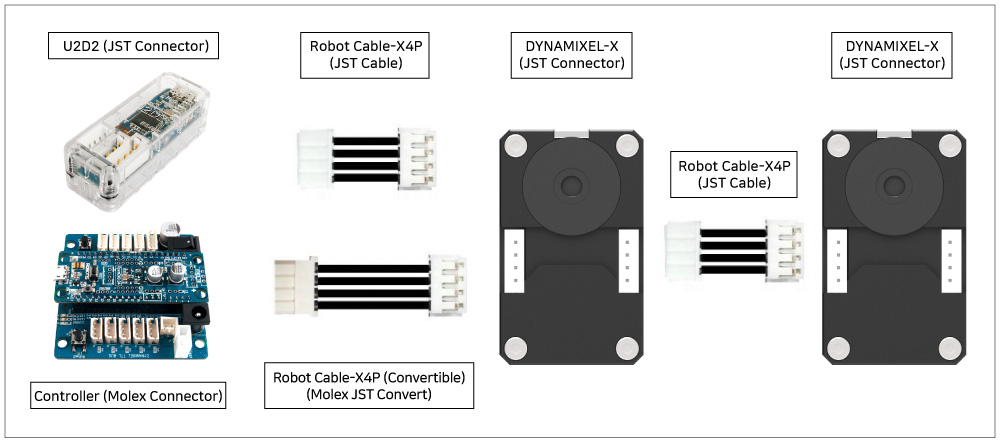

The DYNAMIXEL-X Series adopted a new gold-plated JST connector for secure and reliable communication.

The connector used for the previous DYNAMIXEL is Molex.

To control DYNAMIXEL-X Series actuators via OpenCM or USB2Dynamixel, please use the JST-Molex Convertible Cable enclosed in the package.

However, the Molex-JST convertible cable is NOT included in the XL430 model.

Please purchase a convertible cable when using a controller and interface that supports the JST connector.

| Controller Model | Controller Connector | Cable | DynamixelX Connector | Dynamixel Communication |

| OpenCM+485 Expansion Board | Molex (3P, 4P) | Robot Cable-X3P 180mm (Convertible) | JST-3P | TTL |

| USB2Dynamixel | Molex (3P, 4P) | Robot Cable-X3P 180mm (Convertible) | JST-3P | TTL |

| OpenCR1.0 | JST (3P, 4P) | Robot Cable-X3P (by length) | JST-3P | TTL |

| U2D2 | JST (3P, 4P) | Robot Cable-X3P (by length) | JST-3P | TTL |

| OpenCM+485 Expansion Board | Molex (3P, 4P) | Robot Cable-X4P 180mm (Convertible) | JST-4P | RS-485 |

| USB2Dynamixel | Molex (3P, 4P) | Robot Cable-X4P 180mm (Convertible) | JST-4P | RS-485 |

| OpenCR1.0 | JST (3P, 4P) | Robot Cable-X4P (by length) | JST-4P | RS-485 |

| U2D2 | JST (3P, 4P) | Robot Cable-X4P (by length) | JST-4P | RS-485 |

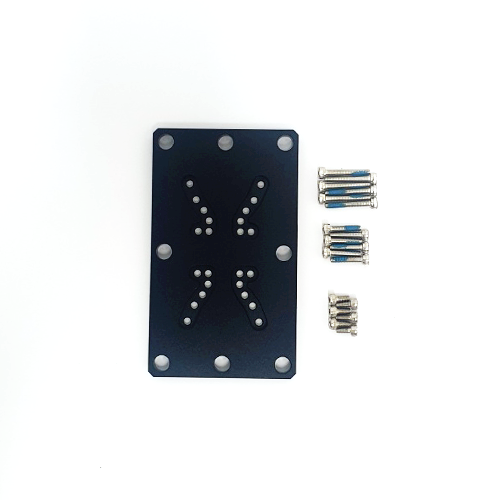

| Model Name | XM540-W150 | |

|---|---|---|

| MCU | Cortex-M3 (72 [Mhz], 32 [bit]) | |

| Input Voltage | Min. [V] | 10.0 | Recommended [V] | 12.0 | Max. [V] | 14.8 |

| Performance Characteristics | Voltage [V] | 12.0 | Stall Torque [N·m] | 7.30 | Stall Current [A] | 4.4 | No Load Speed [rpm] | 53.0 | No Load Current [A] | 0.07 |

| Continuous Operation | Voltage [V] | - | Torque [N·m] | - | Speed [rpm] | - | Current [A] | - |

| Resolution | Resolution [deg/pulse] | 0.0879 | Step [pulse] | 4 | Angle [degree] | 360 |

| Position Sensor | Contactless absolute encoder (12 [bit], 360 [deg]) Maker : ams(www.ams.com), Part No : AS5045 | |

| Operating Temperature | Min. [°C] | -5 | Max. [°C] | 80 |

| Motor | Coreless | |

| Baud Rate | Min. [bps] | 9,600 | Max. [bps] | 4,500,000 |

| Control Algorithm | PID | |

| Gear Type | Spur | |

| Gear Material | Metal | |

| Case Material | Metal(Front, Middle) Engineering Plastic(Back) | |

| Dimensions (WⅹHⅹD) [mm] | 33.5 X 58.5 X 44 | |

| Dimensions (WⅹHⅹD) [inch] | 1.32 X 2.30 X 1.73 | |

| Weight [g] | 0.00 | |

| Weight [oz] | 5.82 | |

| Gear Ratio | 152.3 : 1 | |

| Command Signal | Digital Packet | |

| Protocol Type | Half duplex Asynchronous Serial Communication (8bit, 1stop, No Parity) | |

| Link (Physical) | RS485 Multi Drop Bus | |

| ID | 0 ~ 252 | |

| Feedback | Position, Velocity, Current, Realtime tick, Trajectory, Temperature, Voltage, External Port, etc. | |

| Protocol version | 1.0 2.0(Default) | |

| Operating Mode / Angle | Current Control mode:Endless turn Velocity Control mode:Endless turn Position Control Mode:360 [deg] Extended Position Control Mode:±256 [rev] Current-based Position Control Mode:±256 [rev] PWM Control Mode:Endless turn | |

| Output [W] | - | |

| Standby Current [mA] | 40 | |